Deep Drawn Stampings & Custom Eyelets

Producing a Wide Variety of Deep Draw Metal Stampings

- World Class Customer Service

- Consistent Quality

- Competitive Prices

- On Time Delivery

- In-House Tool Design

- Controlled Process

- QS9000 Requirement Capable

- Practice Lean Manufacturing Concepts

Platt Bros. & Co. has been supplying deep drawn metal stampings and custom eyelets to a variety of industries for over 125 years and is committed to producing quality deep drawn parts on time, with dedicated service, at a fair price. Whatever designed component is specified, be it eyelets, tubes, closed end tubes, grommets, shells, cups, cans, rivets, connectors, caps, sleeves, crimp sleeves or housings, dedicated tool makers assure the end component always meets our customers’ needs.

Quality assurance for deep draw metal stamping at Platt Bros. begins at the raw material stage and continues through 1st article inspection, all production phases, including final inspection and shipment of finished product. Our quality system follows internationally recognized standards and utilizes Statistical Process Controls and Statistical Quality Controls to maintain and stimulate continual improvement of our product, such that our customer expectations are met or exceeded.

Specifications for Our Deep Drawn Stampings

Metals

Tolerances / Dimensions

- Stainless Steel

- Aluminum

- Brass

- Copper Based Alloys

- Titanium

- Precious Metals

- Clad and Pre-Plated Materials

- Cold Rolled Steel

- Inside and Outside Diameters: ±0.001″

- Length Dimensions: ±0.003″

- Radius Dimensions: ±0.003″

- Material Thickness: 0.004″ – 0.040″

Specialty Tool Design

Our CAD-CAM system enables our experienced Engineering staff to custom design complex tooling and produce quality deep drawn metal stampings to your specifications. We fabricate from ferrous, nonferrous, pre-plated, clad materials and many special alloys . . .

Deep Drawn Stamping Configurations

Drawn metal parts may be produced in many configurations. Rounds, tapers, ovals, squares, and other irregular shapes. Secondary-type operations can be incorporated into PRIMARY tooling to accomplish the following:

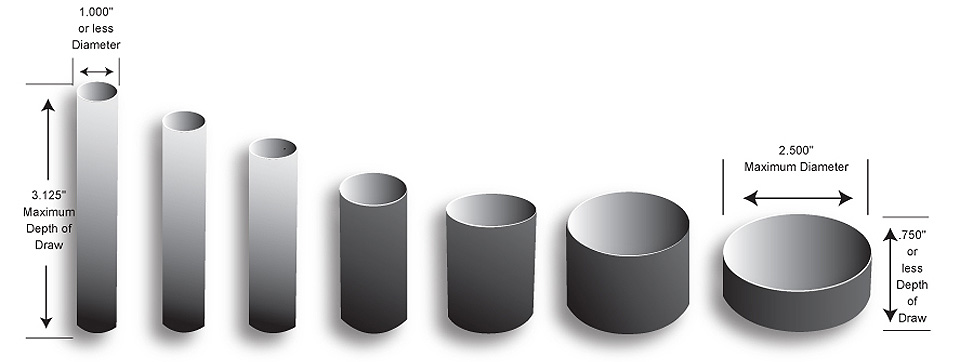

Upper Range: Depths to 3.125″, Diameters to 2.500″

We also offer a variety of standard eyelets for which we maintain tooling. Some active items are stocked.

Industries Served

We have an impressive portfolio of manufacturing and suppling quality deep drawn stampings for a wide variety of industries and applications including:

Aerospace

Automotive

Communications

Construction

Control Valves

Electronics

Lighting

Medical

Military

Sensors / IoT