Quality Assurance

Proudly Meeting or Exceeding Your Quality Requirements

The Platt Brothers and Company is proud of it’s excellent reputation for Quality Assurance. The Eyelet Manufacturing System is ISO9002 certified, an internationally recognized standard for quality management. In addition, we have our own high expectations for quality in all aspects of doing business. All departments are represented on the Quality Assurance Team. From obtaining a clear understanding of your requirements, to meeting or exceeding your specifications, we use our expertise, procedures, experience and processes to provide the quality you expect.

Raw materials are inspected & analyzed, and the production process is subjected to a series of internal reviews & audits to achieve process control for all products. Automatic electronic shut-off sensors on our manufacturing equipment offer added protection against the possibility of broken tooling, in case of product jam. Identified parts characteristics are verified throughout our process. Final inspection is performed utilizing state-of-the-art equipment before the products are shipped.

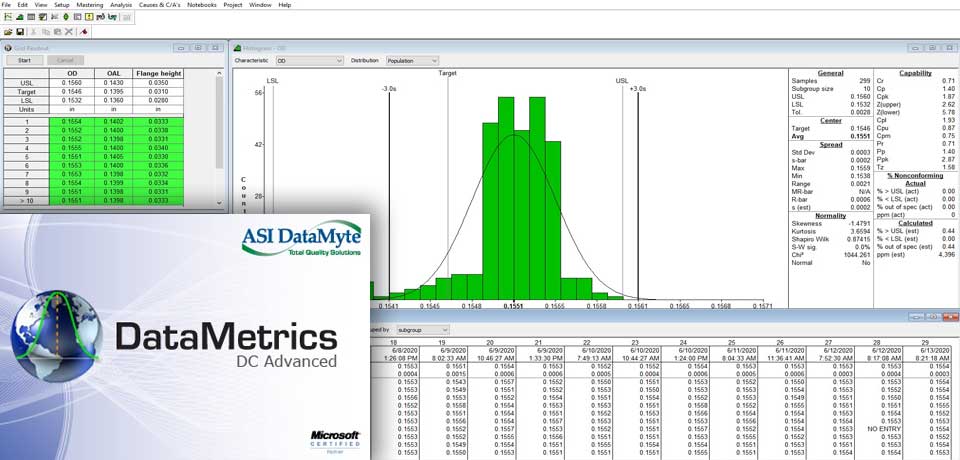

On-going Statistical Process Control (SPC) techniques are used to identify, control and improve the processes & procedures that result in a quality product. Our employees are trained to participate in this important process. Your satisfaction with our products & services provides positive reinforcement for this extensive Quality Effort.

- ISO 13485:2016 Certification (PDF)

- ISO 9001:2015 Certification (PDF)

- KTA-Tator Slip Co-efficient/Creep Deformation

- ASTM

- Mil-Spec

- ANSI

- RoHS Compliant

- DataMyte SPC

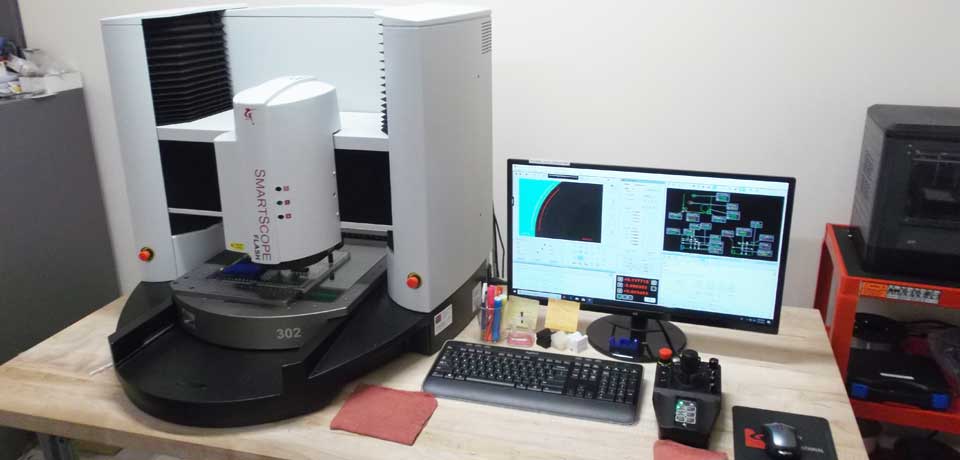

- SmartScope Optical Gage

- Dimensional

- Process Control Plans

- Custom Automated Vision Inspection System

- Visual 50X Microscopes

- Metallographic Analysis

- Cross Sectioning

- Tensile Testing

- Hardness Testing

- Atomic Absorption

- OES

- Resistivity

- Advanced Cross Functional Quality Teams