Zinc Wire for Thermal Spray / Metalizing

Corrosion Protection for a Variety of Applications

Platt Brothers & Company manufactures zinc wire and zinc/aluminum alloy wires used for Zinc Thermal Spray, often called Metalized Coatings. Zinc and zinc alloy wire sprayed coatings are integral steps in the manufacture of various electronic, capacitor, automotive, heat exchanger and tube & pipe products. Thermally Sprayed Zinc based alloy wire coatings are also used in the Corrosion protection of bridges, locks & dams, above ground storage tanks, light poles, and other critical infrastructure.

Zinc Wire Specifications Overview:

- 99.99%+ – Pure Zinc

- 98% Zinc/2% Aluminum

- 85% Zinc/15% Aluminum

- 78% Zinc/22% Aluminum

- 0.057″

- 0.064″

- 0.079″

- 0.091″

- 0.125″

- 0.1875″

- With Federal, State and local regulations limiting VOCs, durable, cost effective coating selection has become increasingly difficult.

- A thermally sprayed coating of Plattzinc 302, 98/2, 85/15 and 78/22 has NO VOCs.

- Steel Infrastructure: Bridges, Walkways, Bridge Bearings Railings, Piers

- Waterways, Gates, Locks Repair of Galvanized Coatings

- Exterior of Steel and Iron pipes

- Gas Cylinders

- Boat Trailers and other Marine equipment

- Tanks

- 50 pound paper wrapped coils

- 25, 40 and 60 pound plastic spools

- Continuous wind 500 pound fiber payoffpack drums

- Level or random wound spools

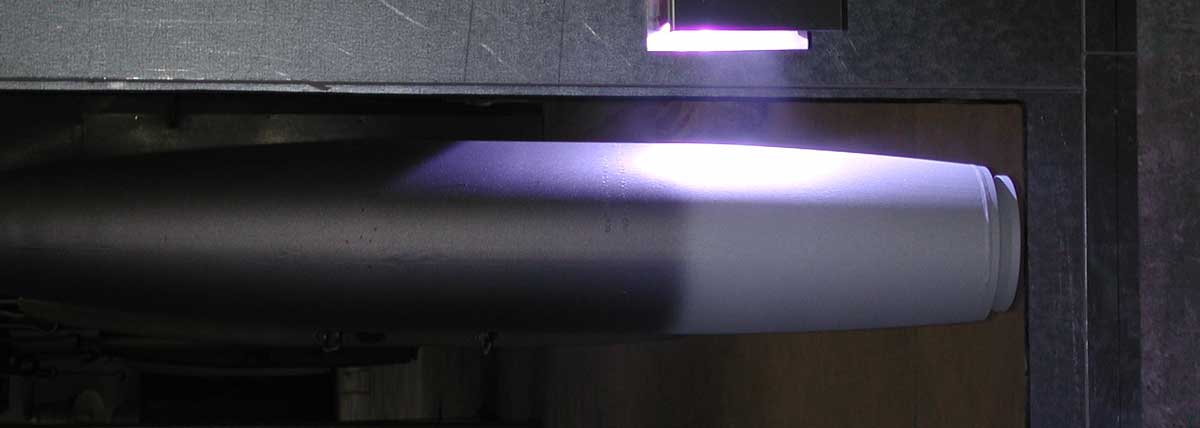

Featured Zinc Wire Portfolio Project – The Rainbow Bridge

Massive projects such as the Rainbow Bridge at the USA/Canadian border crossing at Niagara Falls, shown above, that was metalized with Plattzinc Alloy 1315, 85/15 Zinc/Aluminum. The project was performed by Clara Ind., Thunder Bay, Ontario using TMS Metalizing Systems, Silverdale, WA Bridgemaster Thermal Arc Spray systems during 2002 and 2003. The 85/15 Zn/Al Alloy Metalized Coating System was chosen after extensive research by the Niagara Falls Bridge Commission as when sprayed onto steel the 85/15 alloy produces a coating with the best anti corrosion noble characteristics of both the Zinc and Aluminum metals for optimum corrosion protection. The corrosion resistance of this zinc wire alloy is especially effective on steel against sodium chloride(salt), sulfur dioxide and marine environments.